When it comes to making changes to our food safety practices, we want to be sure we are doing right by our entire distribution channel. We need to make sure that distributors and retailers do not have to go through long mass product shortages. We need to make sure the cost of the food is maintained at an affordable level and we need to make sure that the customer is confident that they are feeding the safest, highest quality food available.

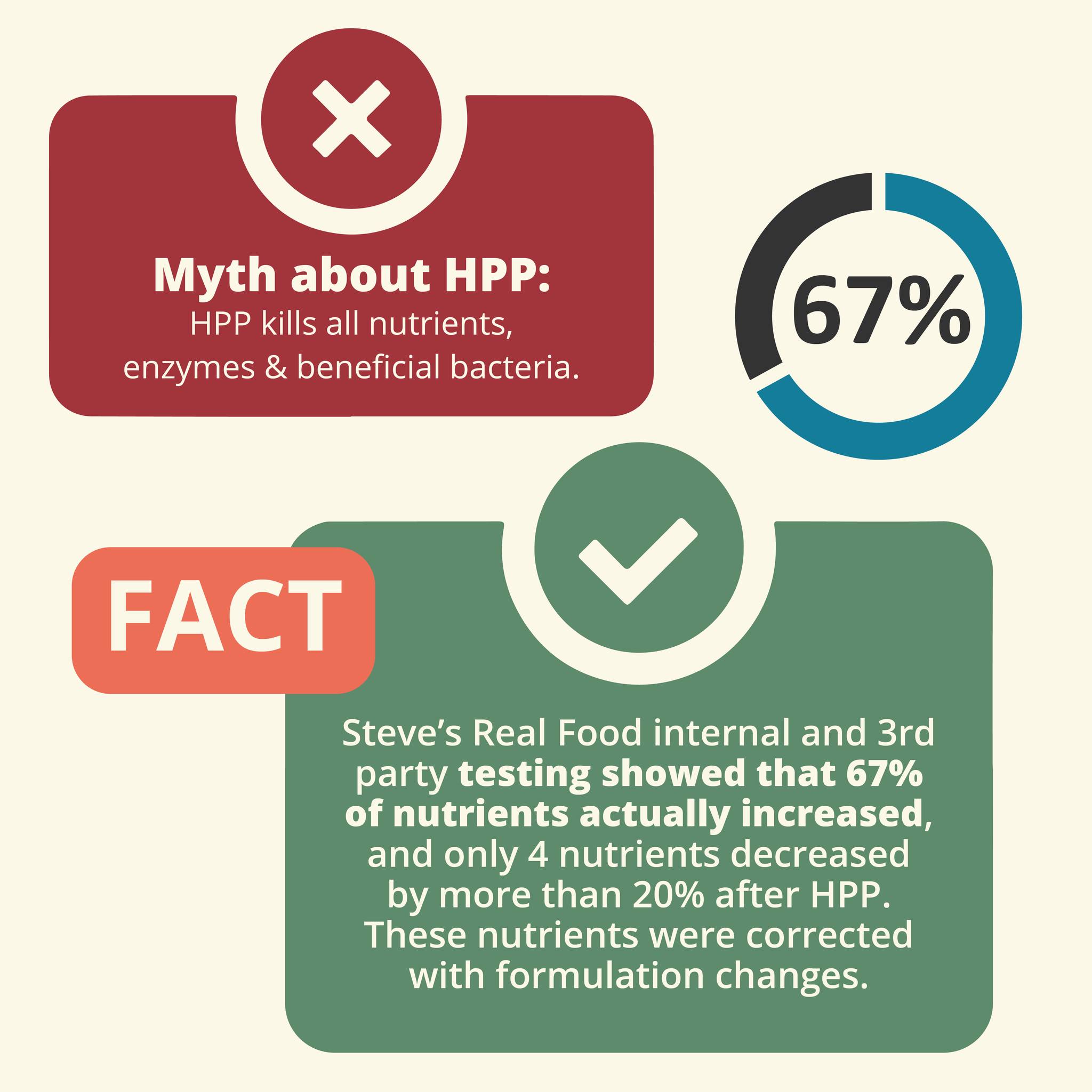

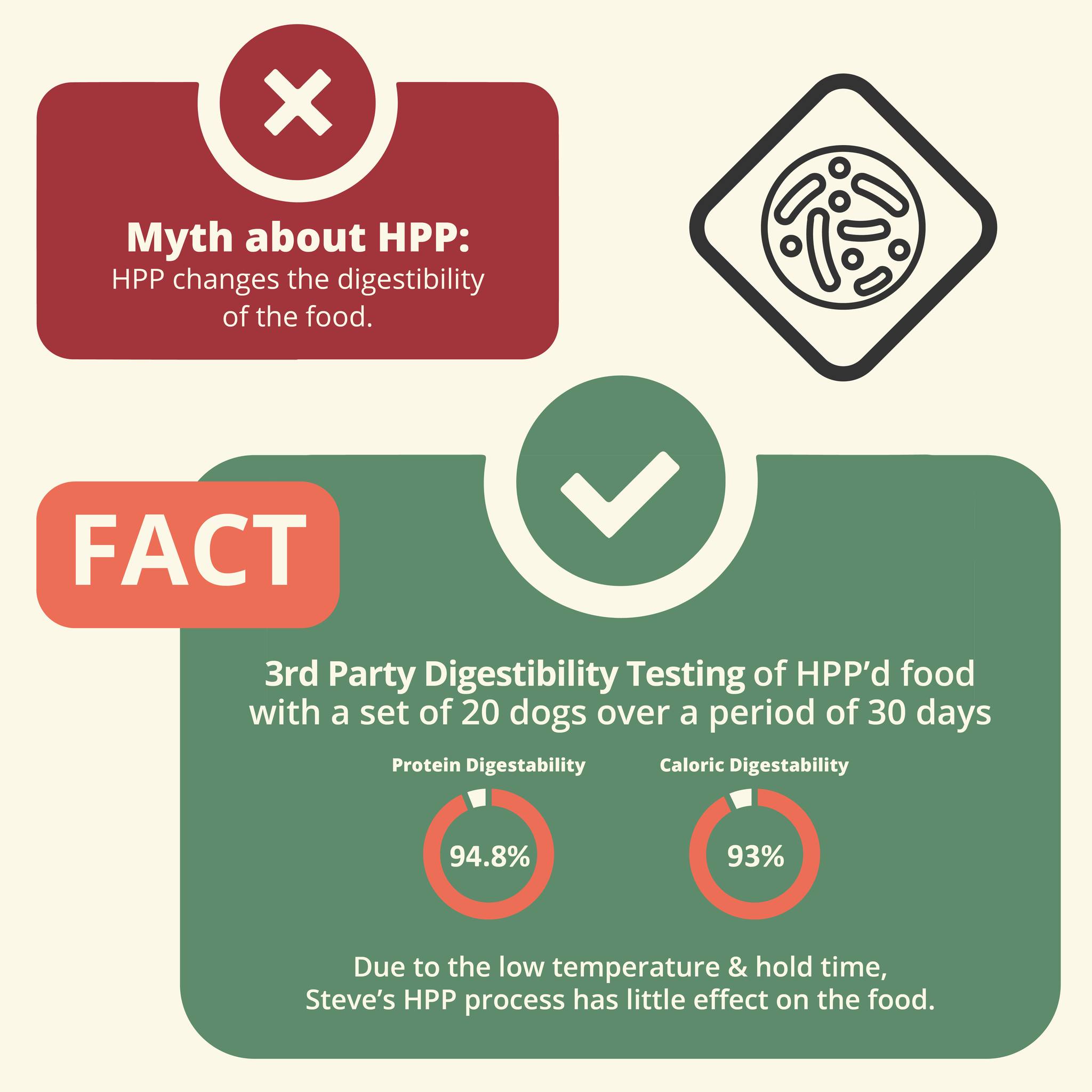

We have spent several months evaluating different options for our food safety program, from test-and-hold procedures to pathogen-targeted probiotic sprays, to HPP. We have decided to use HPP for all our formulas. As mentioned, we conducted many tests while going through the food safety evaluation period. We ran tests on HPP and non-HPP food to determine the effect on vitamins, minerals, enzymes, probiotics, and fats. We were happy to discover that HPP has a minimal effect on the nutritional constitution of the pet food. Click here to view the results of our rigorous testing.

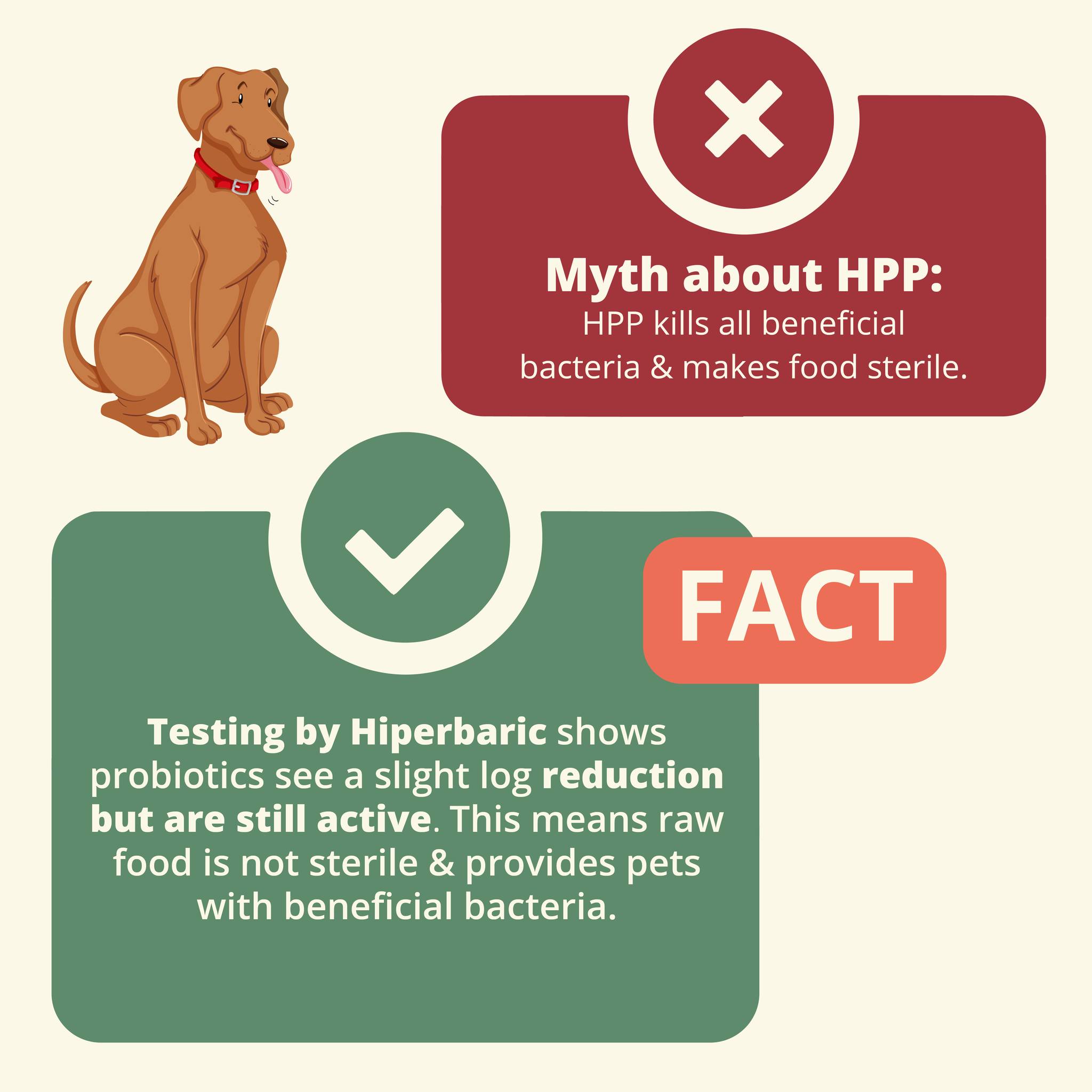

In particular, we found that the overall protein levels of the formulas increased, due specifically to an increase in the amino acid tryptophan. Fats remained relatively the same, and calcium and phosphorus decreased, but remained above AAFCO’s requirements and the calcium to phosphorus ratio remained at optimal levels. Iron increased, within safe levels. The only change that we feel the need to specifically address is the observable decrease in vitamin A, which we will counteract by increasing liver amounts (a great natural source of vitamin A) in the diets which contain poultry. Surprisingly, we found out there is no effect on enzymes and little effect on probiotics. However, we have chosen to incorporate additional probiotics after the HPP process to have another value-added ingredient.

With these changes, we will also be increasing the frequency of nutritional tests we conduct on our products so we may closely monitor and/or detect any variance. Overall, we are excited about the changes we are making. We feel this will eliminate possible exposure to pathogens and improve the quality of the food. These changes will allow us to keep up on our current production schedule and continue to offer products that are as high-quality and affordable as possible. There will be no new changes to the price of the food due to HPP.

We thank you for your continued support and look forward to all the great things we will be doing in 2019. Please feel free to email [email protected] with any questions or concerns. This email goes directly to our product development team who reviews each email and discusses all customer comments on a weekly basis.

The Steve’s Real Food Team

Listen to This Podcast with Our CEO Sitting Down to Talk HPP with the Cold Pressure Council

High-Pressure Pasteurization FAQ.

Why did you choose to start using HPP?

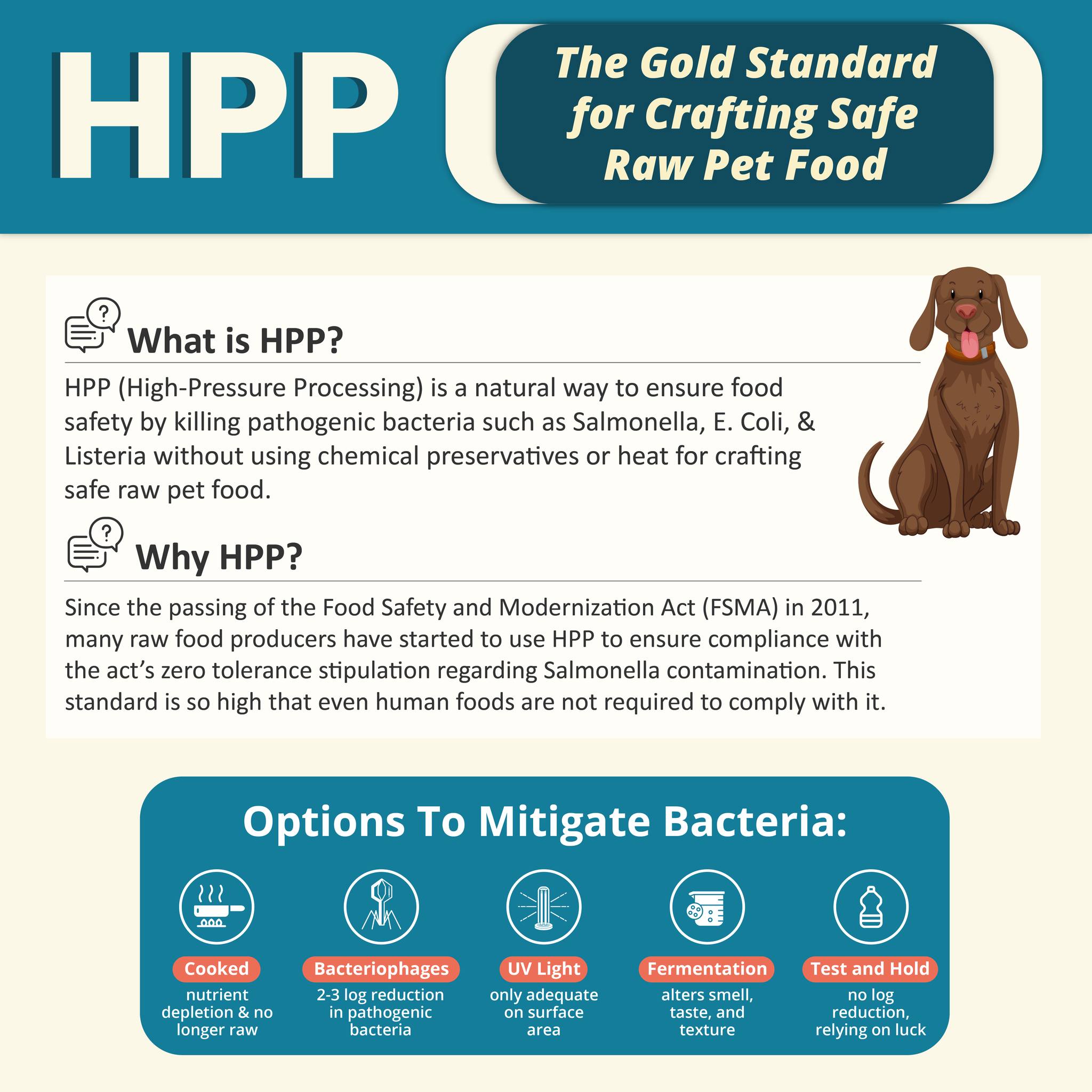

As a company, we have chosen to use HPP on our products only after many two years of research of various kill step processes that would minimize risks associated with harmful pathogens. Our focus was on keeping our pets diet at the highest quality possible without compromising convenience and affordability. HPP is hands down the most effective with minimal effect on the nutritional adequacy of the food.

When did you start to do HPP?

We started distributing batches of poultry products that have gone through the HPP process in February 2019. After continued research, we decided to use HPP on all frozen products in January 2020.

What is HPP and what is the process?

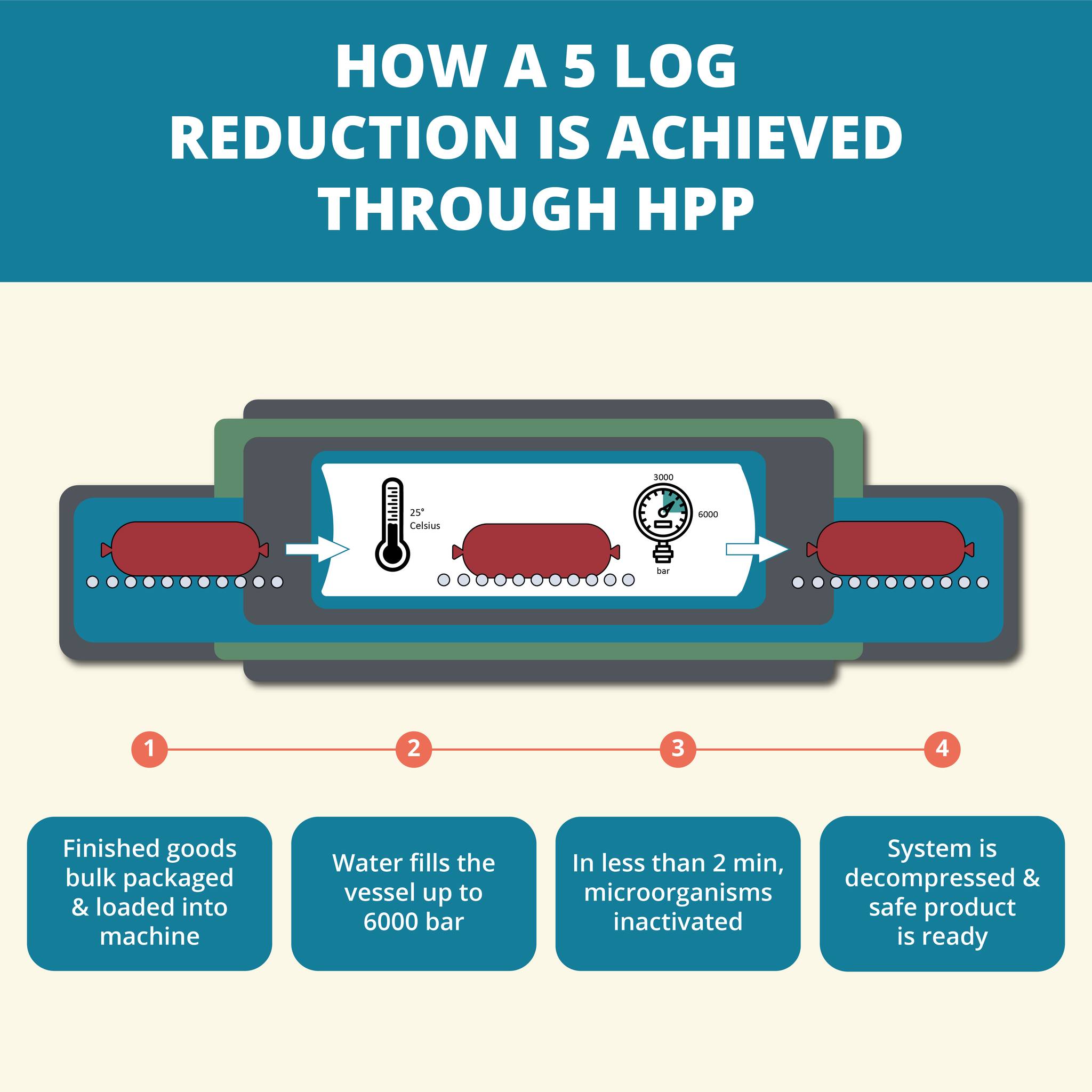

Frozen product (29-degrees) is placed in a chamber filled with chilled water (35-38 degrees) it is then pressurized for 160 seconds at 87 PSI (pressure square inch) this validates a 5 log reduction. Water temperature in the chamber only increases by 1-2 degrees which does not change product temperature.

High-Pressure Processing = high pressure, NOT heat.

Does HPP change or kill natural Enzymes or minerals?

After many third-party lab tests, we found that the overall protein levels of the formulas increased, due specifically to an increase in the amino acid tryptophan. Fats remained relatively the same, calcium and phosphorus decreased but remained above AAFCO’s requirements, and the calcium to phosphorus ratio remained at optimal levels. Iron increased, within safe levels. The only change that we feel the need to specifically address is the observable decrease in vitamin A, which we will counteract by increasing liver amounts (a great natural source of vitamin A) in the diets which contain poultry. Surprisingly, we found out there is no effect on enzymes and little effect on probiotics.

What proof do you have that it did not affect enzymes?

We have done several third-party tests to evaluate the overall nutritional content of HPP VS non-HPP food and we would be happy to provide that information for you.

Here are the details of the HPP on pet food study we did.

Does HPP make the food less palatable?

No, HPP does not alter the palatability of the food. There is a slight texture change due to re-grinding the food after the HPP process. Some dogs notice this and may question the difference, but we have found that it only takes a little while and they are back to their normal excited temperament for the food.

Is there a color or texture change to the HPP products?

No there is not a color change to any of the HPP products, we use the same USDA inspected ingredients. If you notice a color change it is most likely due to the natural changes in the color of the meat from batch to batch.

What benefits does HPP have?

It inactivates foodborne pathogens such as Salmonella, E Coli & Listeria without changing the nutritional value of the food. It offers a safer option for consumers who are worried about food safety, who have small children or are immune-compromised – Or who have a pet who is immune-compromised. It also eliminates the need for a more severe and denaturing process such as radiation, chemical preservatives or thermal processing.